Bescutter Double-Point Servo Press (80T–315T)

Engineered for precision, performance, and reliability, the Bescutter Double-Point Servo Press delivers exceptional forming accuracy across a wide range of metal stamping applications. Designed with a C-type frame and dual-point drive system, this press provides uniform pressure distribution and enhanced die life—ideal for complex, high-tolerance components.

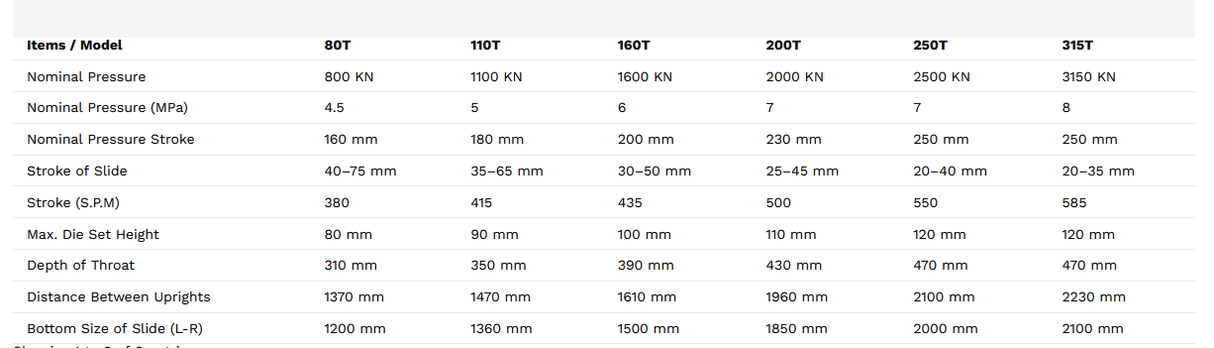

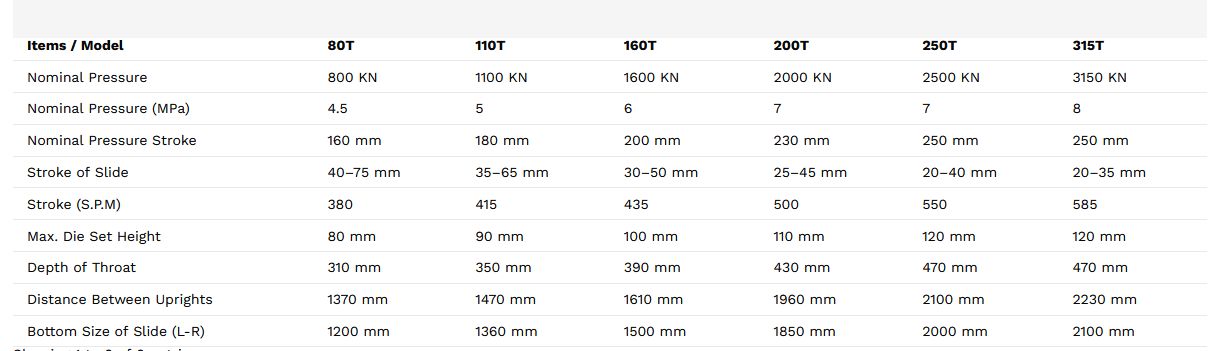

Powered by a servo-driven motor, each model (80T, 110T, 160T, 200T, 250T, and 315T) offers full-stroke programmability, allowing operators to fine-tune slide motion, speed, and dwell positions to match specific material requirements. The result is faster setup, reduced vibration, and superior part consistency compared to conventional mechanical presses.

Built for continuous production environments, the Bescutter Double-Point Servo Press combines heavy-duty construction with advanced electronic control for stable operation under high loads. Its efficient design reduces noise, energy consumption, and maintenance demands—helping manufacturers improve productivity without compromising precision.

Key Features:

-

Double-Point Drive: Ensures balanced force distribution and minimizes frame deflection.

-

Servo Technology: Programmable slide motion for optimized forming speed and accuracy.

-

High Rigidity C-Frame: Provides excellent stability and extended tool life.

-

Energy-Efficient Motor System: Reduces operational costs while maintaining consistent torque.

-

User-Friendly Control Interface: Simplifies setup and real-time parameter adjustments.

-

Available Capacities: 80T, 110T, 160T, 200T, 250T, and 315T.

Applications:

Ideal for precision metal stamping, deep drawing, forming, and progressive die operations in industries such as automotive, appliance, electronics, and general manufacturing.