Bescutter Single-Crank Press (25T–260T)

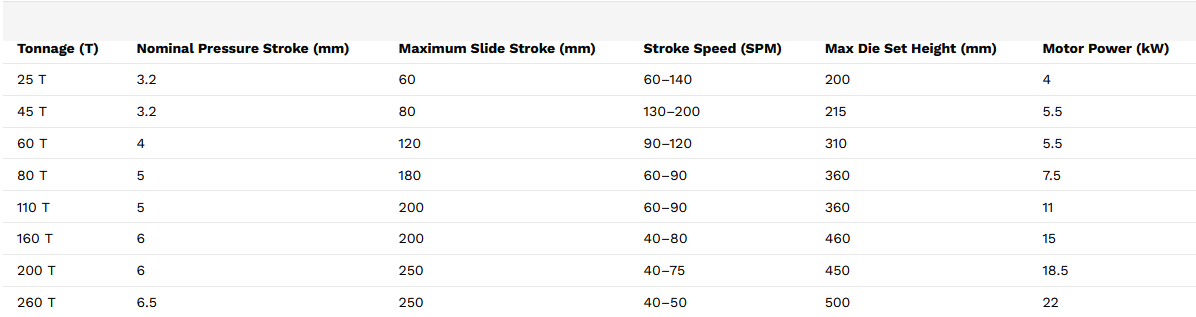

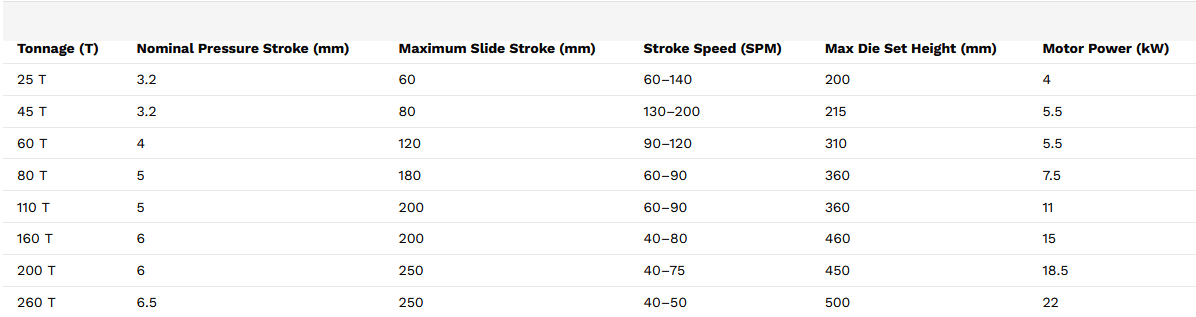

Built for precision, reliability, and efficiency, the Bescutter Single-Crank Press Series delivers consistent performance for a wide range of stamping and forming operations. Available in 25T, 45T, 60T, 80T, 110T, 160T, 200T, and 260T models, each press is engineered to JIS-1 standards, ensuring superior accuracy and long-term durability in demanding production environments.

Featuring a high-rigidity welded steel frame and six-sided slide guide system, this press maintains perfect alignment during high-speed operation. A dry pneumatic friction clutch provides smooth, responsive engagement, while hydraulic overload protection safeguards the press and tooling against damage from excess force.

Operators benefit from an automatic lubrication system, variable stroke control, and mold height adjustment—automatic on most models and manual on lighter variants—allowing for rapid setup changes and enhanced productivity.

With its robust design and precision mechanics, the Bescutter Single-Crank Press is the ideal choice for metal stamping, forming, blanking, and small to medium-sized progressive die operations across industries such as automotive, electronics, appliance, and hardware manufacturing.

Key Features:

-

Meets JIS-1 Precision Standards for accuracy and performance.

-

Rigid Welded Frame minimizes vibration and improves part consistency.

-

Six-Sided Guide Rail System ensures slide stability and extended die life.

-

Dry Pneumatic Friction Clutch for smooth, reliable operation.

-

Hydraulic Overload Protection to prevent equipment damage.

-

Automatic Lubrication & Stroke Adjustment for efficient, low-maintenance operation.

-

Automatic or Manual Mold Height Adjustment (depending on model).

-

Available Capacities: 25T, 45T, 60T, 80T, 110T, 160T, 200T, 260T.

Applications:

Ideal for precision stamping, blanking, forming, and progressive die production in automotive, appliance, and general fabrication sectors.