Apollo A – High-Strength, Manganese and Wear-Resistant Steel

GREAT CHOICE! THIS PRODUCT QUALIFIES FOR FREE SHIPPING (*SOME EXCEPTIONS APPLY).

Apollo A – High-Strength, Manganese and Wear-Resistant Steel - 1/8" is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

This product qualifies for free shipping offers. (*Some exceptions apply).

Large equipment, bulk or overweight products may incur additional freight charges.

Description

Description

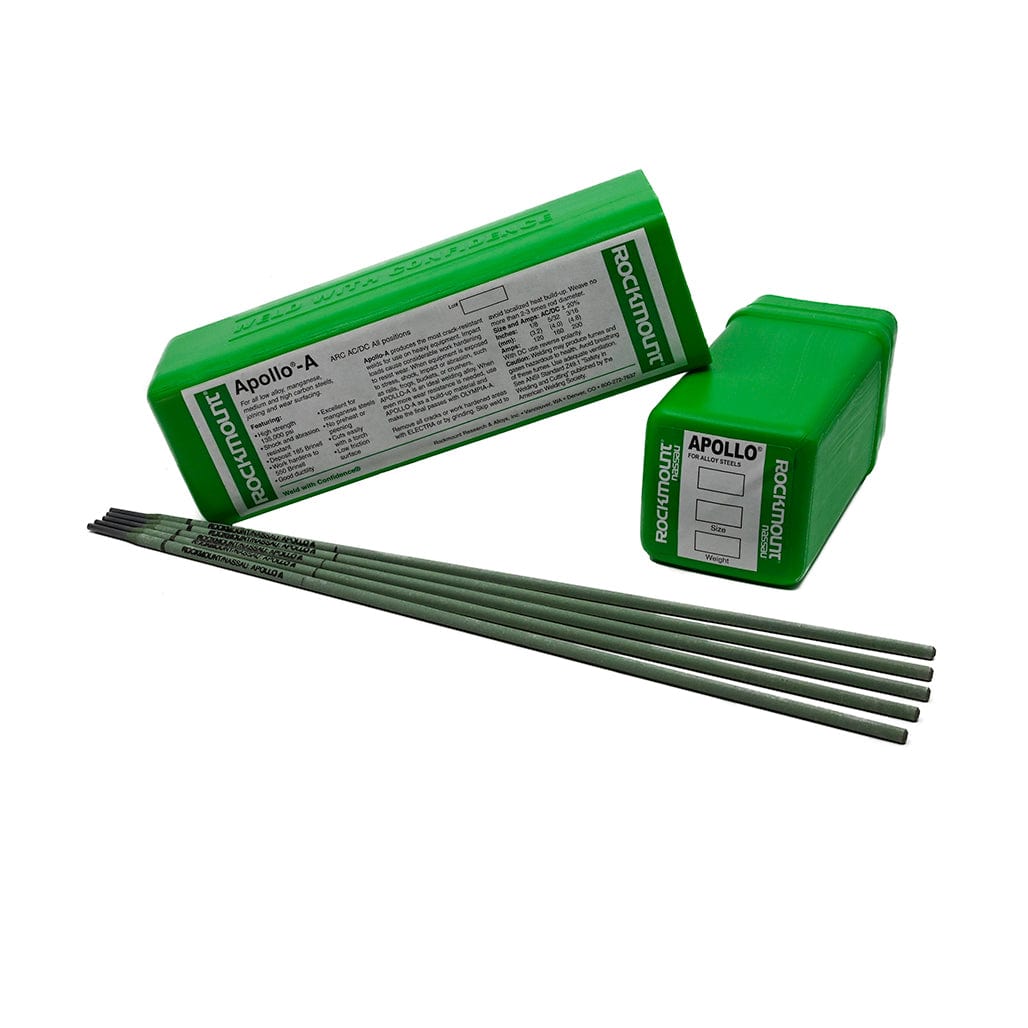

Apollo A Arc Welding Rods – High-Strength Electrodes for Manganese and Wear-Resistant Steel (SMAW) - 2lb Tube

Product Description

Maximum strength and impact resistance for heavy equipment repairs.

Apollo A rods are engineered to deliver crack-resistant, work-hardening welds on low alloy, manganese, and carbon steels. Built for the most demanding applications, Apollo A provides a 135,000 psi tensile strength weld with 30% elongation and the ability to harden under stress—making it ideal for shock, impact, and abrasion-prone repairs.

Use Apollo A for high-wear applications like crusher hammers, rail frogs, dragline chains, and manganese wear plates. For even greater wear resistance, overlay with hardface alloys like Olympia, Omega, or Zeta.

Key Features

- 135,000 psi tensile strength with 30% elongation

- Deposits work harden up to 55 RC

- Ideal for manganese, carbon, and medium/high alloy steels

- Excellent for metal-to-metal wear surfaces

- No preheat or peening required

- Flux coating resists moisture

- Cuts easily with a torch

- Operates on AC or DCEP

Packaging & Sizes

- Electrode length: 14"

- Sold in 2 lb, 5 lb, or 11 lb plastic tubes

- Available diameters:

- 1/8"

- 5/32"

- 3/16"

Recommended Amperage Settings (±20%)

- 1/8": 120 Amps

- 5/32": 160 Amps

- 3/16": 200 Amps

- Use AC or DC reverse polarity (DCEP)

Welding Instructions

- Remove all cracks or work-hardened areas with Electra or by grinding

- Skip weld to avoid localized heat buildup

- Weave no more than 2–3 times the rod diameter

Applications

- Crusher hammers and buckets

- Manganese wear plates and dragline chains

- Rails, frogs, and crossovers

- Pins, linkages, and high-impact joints

- General buildup on abrasion-prone components