Apollo A – Acier à haute résistance, au manganèse et résistant à l'usure

EXCELLENT CHOIX ! CE PRODUIT BÉNÉFICIE DE LA LIVRAISON GRATUITE (*CERTAINES EXCEPTIONS S'APPLIQUENT).

Apollo A – Acier à haute résistance, au manganèse et résistant à l'usure - 1/8" est en rupture de stock et sera expédié dès qu’il sera de retour en stock.

Impossible de charger la disponibilité pour le Service de retrait

Livraison et expédition

Livraison et expédition

Ce produit est éligible à la livraison gratuite. (*Certaines exceptions s'appliquent).

Les équipements volumineux, les produits en vrac ou surdimensionnés peuvent entraîner des frais de transport supplémentaires.

Description

Description

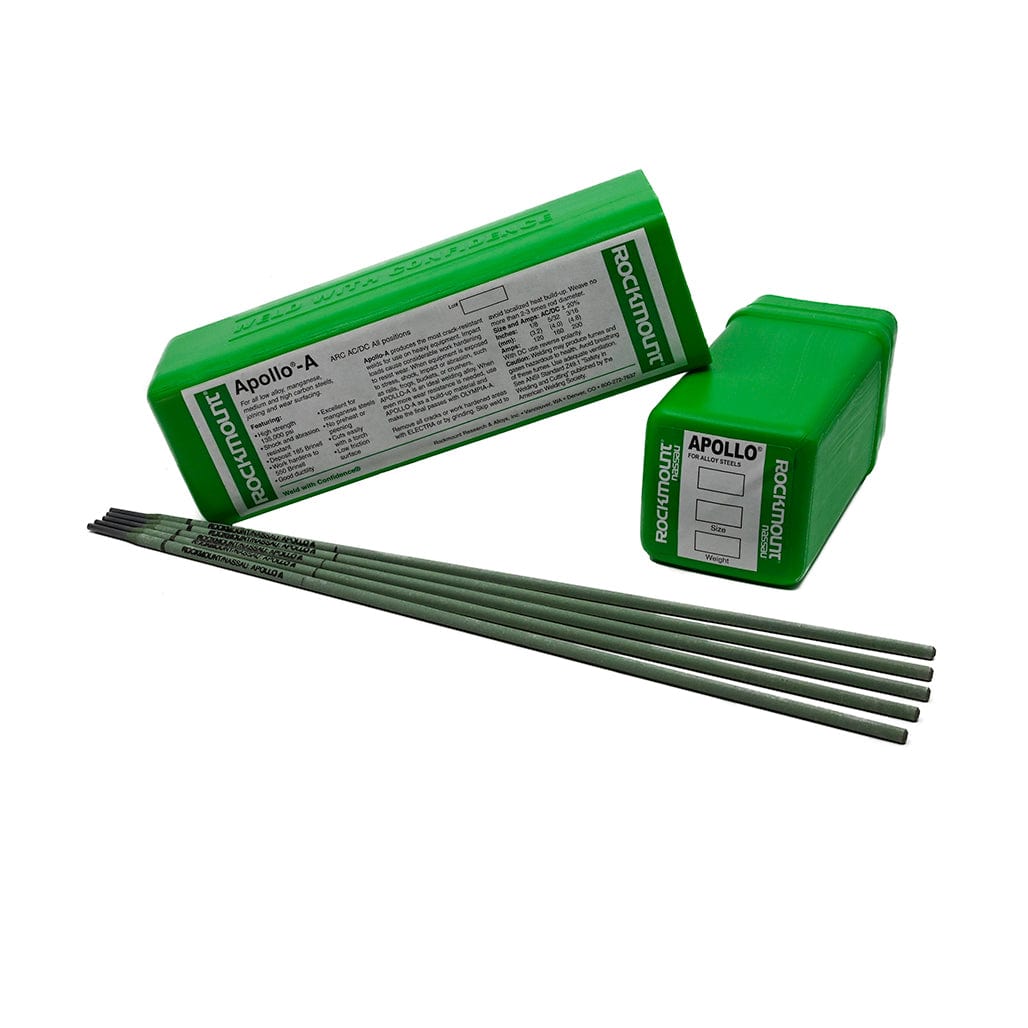

Baguettes de soudage à l'arc Apollo A – Électrodes haute résistance pour le manganèse et l'acier résistant à l'usure (SMAW) – Tube de 907 g (2 lb)

Description du produit

Résistance et solidité maximales aux chocs pour la réparation d'équipements lourds.

Les baguettes Apollo A sont conçues pour réaliser des soudures résistantes à la fissuration et à écrouissage sur les aciers faiblement alliés, au manganèse et au carbone. Destinées aux applications les plus exigeantes, les baguettes Apollo A offrent une résistance à la traction de 135 000 psi, un allongement de 30 % et une capacité d’écrouissage sous contrainte, ce qui les rend idéales pour les réparations soumises aux chocs, aux impacts et à l’abrasion.

Utilisez Apollo A pour les applications à forte usure telles que les marteaux de concasseur, les cœurs d'aiguillage, les chaînes de dragline et les plaques d'usure en manganèse. Pour une résistance à l'usure encore plus élevée, appliquez un revêtement dur en alliages comme Olympia, Omega ou Zeta.

Caractéristiques principales

- résistance à la traction de 135 000 psi avec un allongement de 30 %

- Les dépôts durcissent jusqu'à 55 RC

- Idéal pour les aciers au manganèse, au carbone et moyennement/fortement alliés.

- Excellent pour les surfaces d'usure métal sur métal

- Aucun préchauffage ni grenaillage requis

- Le revêtement de flux résiste à l'humidité

- Se coupe facilement au chalumeau

- Fonctionne sur courant alternatif ou continu.

Emballage et tailles

- Longueur de l'électrode : 14 pouces

- Vendu en tubes de plastique de 2 lb , 5 lb ou 11 lb

- Diamètres disponibles :

- 1/8"

- 5/32"

- 3/16"

Réglages d'ampérage recommandés (±20%)

- 1/8 : 120 ampères

- 5/32 : 160 ampères

- 3/16 : 200 ampères

- Utiliser une polarité inversée AC ou DC (DCEP)

Instructions de soudage

- Éliminez toutes les fissures ou zones écrouies à l'aide d'Electra ou par meulage.

- Éviter la soudure pour prévenir une accumulation de chaleur localisée.

- Tissez une longueur ne dépassant pas 2 à 3 fois le diamètre de la tige.

Applications

- Marteaux et godets de concasseur

- plaques d'usure en manganèse et chaînes de dragline

- Rails, aiguillages et croisements

- Axes, articulations et joints à haute résistance

- Accumulation générale sur les composants sujets à l'abrasion