Soudage à l'électrode enrobée : votre guide des techniques, conseils et dépannage

Le soudage à l'électrode enrobée, également appelé soudage à l'arc métallique protégé (SMAW), est un procédé polyvalent et fiable, plébiscité par les soudeurs des secteurs de la construction, de la fabrication et de la réparation. Robuste, portable et fiable, il est idéal pour une vaste gamme d'applications.

Qu'est-ce que le soudage à l'électrode enrobée ?

Le soudage à l'électrode enrobée utilise une électrode enrobée de flux pour créer un arc électrique entre l'électrode et le métal. Le flux fond pendant le soudage, libérant un gaz de protection qui préserve la soudure de toute contamination. Portable et utilisable dans divers environnements, ce procédé est particulièrement efficace pour les travaux en extérieur.

Avantages et inconvénients

Le soudage à l'électrode enrobée est reconnu pour sa simplicité et sa capacité à travailler divers métaux et dans différentes conditions.

-

Avantages : Portable, fonctionne bien en extérieur et par temps venteux, aucun gaz de protection n'est nécessaire.

-

Inconvénients : Plus lent que des méthodes comme le soudage MIG et nécessite l’élimination des scories.

Le soudage à l'électrode enrobée excelle là où la flexibilité et la robustesse sont nécessaires, mais pour des résultats rapides ou plus nets, il vaut mieux envisager d'autres options.

Soudage à l'arc pour débutants

Vous débutez en soudage à l'électrode enrobée ? Concentrez-vous sur les bases :

- Maintenir une longueur d'arc constante.

- Contrôlez la vitesse de déplacement pour des soudures uniformes.

- Utilisez l'électrode appropriée à votre matériau.

Pour de meilleurs résultats, mettez en pratique ces compétences en veillant à un équipement adéquat et au respect des consignes de sécurité.

Conseils pour une meilleure soudure à l'électrode enrobée

- Maîtriser la manipulation constante des électrodes pour des soudures plus lisses.

- Ajustez les paramètres actuels en fonction du type et de l'épaisseur du matériau.

- Minimisez les défauts tels que la porosité et les contre-dépouilles en perfectionnant votre technique.

Apprendre auprès de soudeurs expérimentés et utiliser les ressources en ligne peuvent accélérer votre progression.

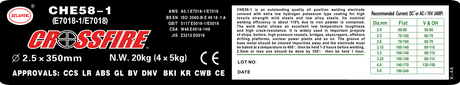

Choisir le bon équipement et les électrodes

Votre équipement dépend du matériau à souder et de votre budget. Les postes à souder à l'arc varient en puissance et en taille, tandis que les électrodes diffèrent par la composition du flux et leur diamètre. Adaptez votre matériel aux besoins de votre projet et investissez toujours dans des outils de qualité pour une fiabilité optimale.

Problèmes courants et solutions

Le soudage à l'électrode enrobée peut présenter des problèmes tels que des projections, une instabilité de l'arc ou une fusion incomplète. Résolvez ces problèmes en :

- Ajustement des paramètres actuels pour un meilleur contrôle.

- Nettoyer les surfaces pour éviter toute contamination.

- Amélioration des techniques pour éviter les défauts de soudure.

Applications dans tous les secteurs d'activité

Le soudage à l'électrode enrobée est largement utilisé dans la construction, la construction navale, la réparation automobile et les travaux de canalisation. Sa capacité à travailler différents métaux le rend essentiel pour la fabrication de structures, les travaux de réparation et les opérations de maintenance.

Projets de soudure en extérieur

Le soudage à l'électrode enrobée est un procédé de choix pour les travaux extérieurs grâce à sa résistance aux intempéries. Le revêtement de flux protège la soudure, ce qui le rend idéal par temps venteux ou dans des conditions météorologiques imprévisibles.

Soudage à l'électrode enrobée vs soudage MIG

Le soudage à l'électrode enrobée est portable et polyvalent, tandis que le soudage MIG offre une vitesse d'exécution plus rapide et des soudures plus nettes. Votre choix dépendra de facteurs tels que le type de matériau, l'envergure du projet et la qualité de finition souhaitée.

Kits de soudage à l'arc économiques

Les postes à souder à l'arc d'entrée de gamme, les porte-électrodes basiques et les consommables abordables rendent le soudage à l'arc accessible aux débutants. Privilégiez un équipement offrant un bon rapport qualité-prix.

Le soudage à l'électrode enrobée demeure une méthode éprouvée pour les soudeurs recherchant flexibilité et durabilité. Avec les outils et les techniques appropriés, c'est un procédé qui offre des résultats robustes et fiables dans d'innombrables applications.