Ligne de presse à ailerons de type H Bescutter (45T–200T)

La ligne de presse à ailettes de type H Bescutter est une solution intégrée à haute vitesse, conçue pour la production de précision d'échangeurs de chaleur à ailettes et de composants associés . Conçu pour l'efficacité, la fiabilité et un fonctionnement continu, ce système allie une automatisation avancée à une ingénierie mécanique robuste afin d'offrir une qualité de production et un rendement exceptionnels.

Dotée d'une structure en H haute rigidité et d'un système de levage hydraulique , la ligne de presse à ailettes Bescutter garantit un mouvement stable, des vibrations minimales et une longue durée de vie des matrices, même lors de productions prolongées. Un système de contrôle piloté par automate programmable gère chaque étape du processus, du dérouleur à l'alimentateur, en passant par la presse et l'empileur automatique, assurant ainsi un fonctionnement synchronisé et un suivi des performances en temps réel.

Grâce à sa capacité de changement rapide d'outillage et à sa conception optimisée pour l'emboutissage progressif à grande vitesse, cette ligne de presse permet des transitions de configuration rapides et une disponibilité maximale. C'est le choix idéal pour les fabricants recherchant précision, automatisation et productivité dans la fabrication d'ailettes d'échangeurs de chaleur.

Caractéristiques principales :

-

Conception à cadre en H haute vitesse : offre une rigidité et un alignement supérieurs en fonctionnement continu.

-

Système de glissières Hydro-Lift : assure un mouvement fluide et stable avec une usure réduite des outils.

-

Mécanisme de changement rapide de matrice : Réduit les temps d'arrêt entre les cycles de production.

-

Ligne entièrement intégrée : comprend un dérouleur, un alimentateur, une presse et un empileur, contrôlés par un système PLC centralisé.

-

Automatisation en temps réel : synchronisation système et surveillance des processus transparentes pour une production constante.

-

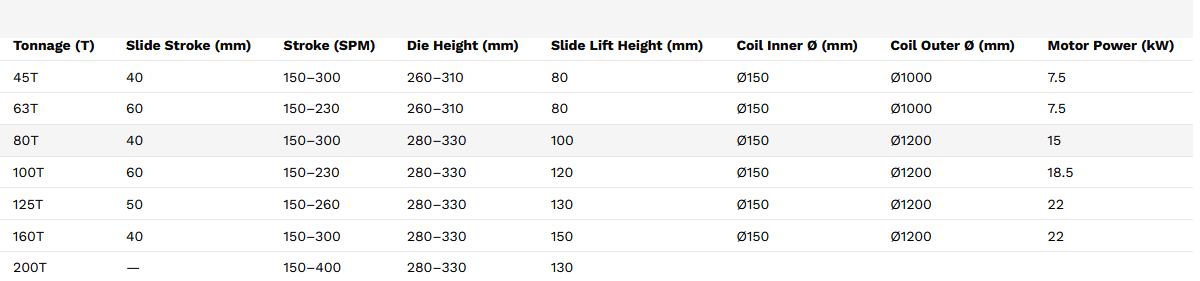

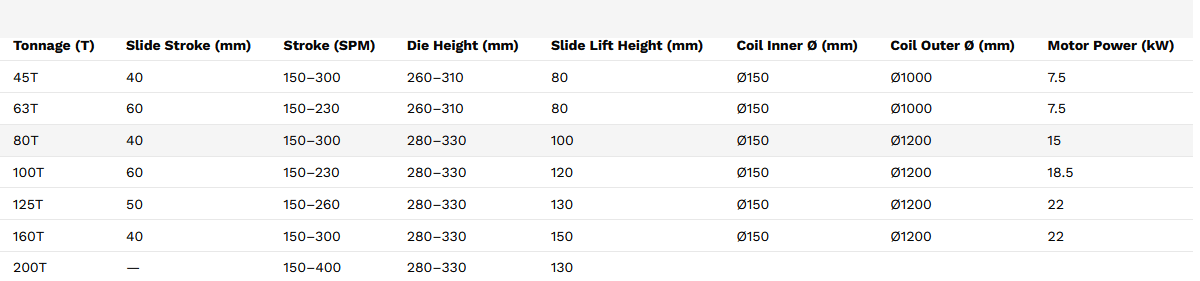

Capacités disponibles : 45T, 63T, 80T, 100T, 125T, 160T, 200T.

Applications :

Conçue spécifiquement pour la production en série d'ailettes d'échangeurs de chaleur , de composants de radiateurs et d'autres pièces métalliques estampées avec précision nécessitant des tolérances serrées et un fonctionnement à grande vitesse.